Company News

Homebrew Steroid Preps

While making injectables:

The number one thing you should be thinking of is practicing isolation of sterilized surfaces and items.

That is, if a piece is sterile, be sure that it doesn't touch anything that is non-sterile. If your hands touch something that you haven't sterilized, swap gloves. Think of it as a tattoo artist, a piercer, or your doc would. Cross-contamination can wreck the final product.

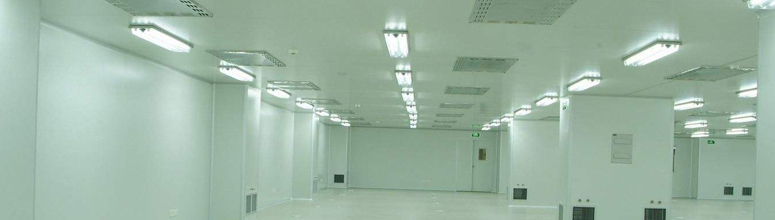

Work in an area or on a tray that you have wiped down with antiseptic solution before use and make sure you are working in an area with no air flow OR under a laminar flow hood(If you have access or know how to make one). If you are using pre-sterilized and sealed vials the airflow issue isn't as important.

Sterilizing your instruments:

Other than your final work surface, the only things you should be worried about keeping sterile are as follows.

1. Stoppers and vials.

I'll go through a method for sterilizing both a bit later, if you aren't using pre-sterilized/sealed vials. Most doing small batches should probably just purchase the sealed vials for ease of use.

2. Your final filters

3. Anything you may be using to transfer the sterilized solution from a larger container to a smaller one if applicable.

Several types of filtration systems and why you should consider using them:

1. Syringe filters

This is probably the most popular type for the small time home brewer.

I would use this method on single batches up to 100ml or for multiple batches for making a single cycle.

2. Sterilized, self contained vacuum filtration.

This would be for single batches in excess of 200ml.

They provides for simple and fast filtration of very large single item batches.

You must practice better sterilization and isolation techniques with most brands.

3. Vacuum driven bottle top filtration systems.

This would be used for VERY large batches; >1L in quantity.

Same guidelines as above, only for use with 1L+ volume vacuum safe media bottles.

For people wishing to use syringe filters, be sure they're STERILE for your final filter. I prefer to prefilter with an unsterilized .45um filter and then do a final pass through a .22um or .2um filter. If you are using a sealed vial you'll want to have one with a male luer lock on it. Some do not come with luer lock ends, but with luer slip.

When using a vacuum filtration system of any kind you'll need a source for the negative pressure. Most people use a hand pump of the variety you can find at any autoparts store, some are more advanced with a small electric pump.

With vacuum systems you'll want to keep your pressure just to the point where it filters smoothly, if you go too high you can and probably will crack the media bottle, then you've wasted a bit of money and need to refilter.

Solvents, co-solvents, and oils

I would recommend that you use all USP grade products, but if you don't feel like shelling out the major cash to buy USP oils, food grade will work. You'll find yourself going through filters much faster with food grade oils than with USP grade oil.

I recommend grape seed, cotton seed, or sesame seed oils for your choices. Though just about anything you can find at the store will work. I wouldn't recommend Wesson, but it will work, you won not be able to shoot that through a 25g needle though.

Never compromise on your solvent choices, all recipes should have a minimum of 1% benzyl alcohol and 5% benzyl benzoate. All should be of USP-24 grade or higher.

Mr. T's 'super solvent' will be sufficient alone if you have a particularly stubborn product you wish to make into an injectable solution. I'm not going to list a bunch of recipes, because we all have our personal preferences to that end. Generally, if you use the lowest possible concentrations of solvents you can to keep your solution from crashing, it is all you need. If you feel more comfortable using 5% ba and 20%bb for everything then you can do that as well.

Sterilization of vials and stoppers:

1. Clean your vials

a. Wash with soap and distilled water, rinsing with distilled water

b. Rinse a second time with an alcohol of your choosing. I prefer to use isopropyl. Acetone is also acceptable

2. Dry and Heat your vials.

a. Place them upside down on a baking sheet that has been properly wiped with an antiseptic.

b. Preheat oven to 350*. Place vials in oven and let set for about 30mins, allow the vials to cool to room temp and then repeat the process.

3. Soak stoppers in a hydrogen peroxide solution for a minimum of 10 mins.

All other items you use that should be sterilized come from the factory sterilized; syringes, needles, and filters.

Shopping list for making injectable items:

1. 1-2 gallons of distilled water.

2. Anti-bacterial dish soap

3. Acetone or isopropyl alcohol >90% purity and hydrogen peroxide

4. Benzyl benzoate

5. Benzyl alcohol

6. USP or food grade oil of your choice

7. 3ml syringes, 10ml syringes, 20-60ml syringes

8. 18g and 3cc Syringe with 25-Guage x 1 1/2"

9. 20 ml Clear Sealed Sterile Glass Vial or unsealed vials

10. If you use unsealed vials you'll need stoppers and caps

11. Whatman Syringe Filter and Coffee Filters

12. Your hormone of choice.

13. Beakers for mixing solutions

What you need to know when making oral solutions:

Most orals will only make suspensions, not solutions. If your hormone doesn't like to go into solution you will have to settle on a suspension that will need shaken before each use.

Shopping list:

1. Suspension medium, ever clear or dehydrated 151 are your best, cheap, bets. Instructions for desiccating Bacardi 151 are easily found searching this forum.

2. A vial of your choice, no sterilization necessary, just be sure it's clean.

3. Hormone of your choice.

4. Benzyl alcohol, peg400, propylene glycol, and ps80 may be necessary for some applications.

5. distilled water for some low dose items that suspend easily. (Clenbuterol for example)

If your solution crystallizes, lower the concentration or add a more powerful solvent and heat till it dissolves. If your suspension crystallizes, add a surfactant and heat till dissolved; it will form finer crystals as it cools.

Point to remember while making oral solutions, each gram of powder displaces just under 1ml of solvent.

Things to know when making oral capsules:

Making capsules properly can be just as tricky as keeping your workplace sterile for making an injectable.

Shopping list for making capsules:

1. capsules, I use size '0' capsules, they hold around 500mg of powder.

2. capsule making machine use a cap let them quick with the tamper.

3. Hormone or 'active' ingredient.

4. Filler, I like to use good ole 'all purpose flour' but anything of the same grain will work well

5. mortar and pestle or Tupperware container or Ziploc bag.

When making capsules it is important to get the densities of the powders you are will be using so that you can correctly mix them.

You'll want to fill and weigh a reasonable selection of capsules so as to get a good number for how much of each ingredient will properly fit into a single capsule. You know how much active ingredient you want to use so that and the amount of each you can fit into capsules are the constants in the ratio and the value you want to find is the amount of filler.

This is the equation you'll want to use X=(Y*Z)/W

X is the amount of filler to be used, Y is the amount of active desired, Z is the amount of filler that will fit into a whole capsule, and W is the amount of active that will fit into a whole capsule. Then multiply X by the number of capsules you wish to make and that is the total amount of filler you will need.

To properly mix your powder and filler you should use the geometric dilution method. That is, add your active ingredient to the bag/Tupperware or mortar, then add an equal amount of the filler, after that has been thoroughly mixed, add in another portion of filler equal to the previous total and mix again, repeat until all filler has been added. This will make for the most even distribution of the active ingredient.

Links:

Copyright © Hubei Honest Biochemical Co., Ltd. All right reserved